Preventive Maintenance

Preventive maintenance is the practice of performing regular, scheduled maintenance on building systems before failures occur. Rather than waiting for equipment to break down (reactive maintenance), preventive maintenance keeps systems operating reliably and extends their useful life.

Accessing Preventive Maintenance

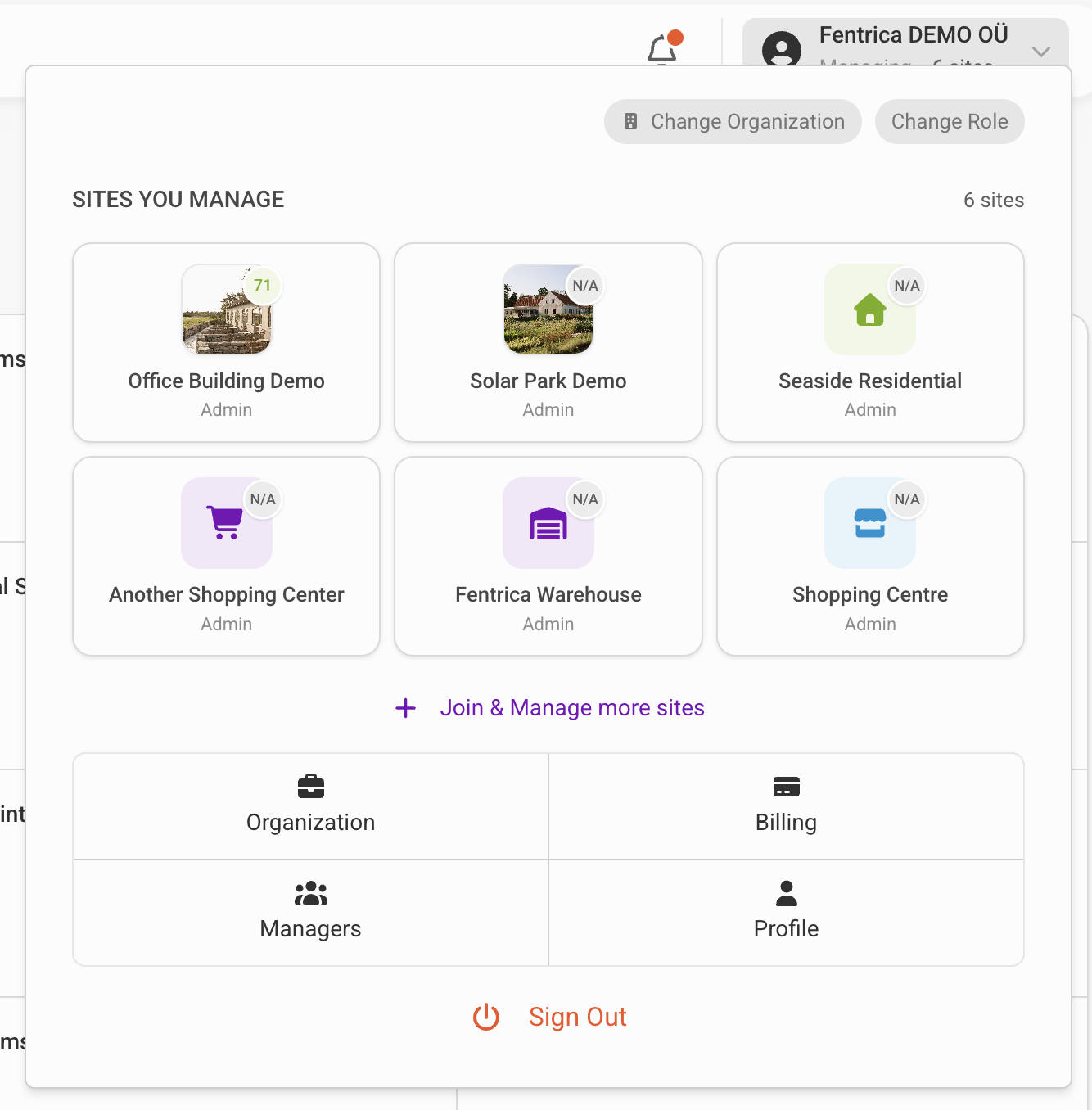

Open the site you manage from the top navigation menu, then select Preventive Maintenance from the site menu.

Why preventive maintenance matters

Reduced Downtime

Equipment failures cause unexpected downtime, tenant complaints, and emergency repair costs. Scheduled maintenance catches problems early, when they are easier and cheaper to fix.

Extended Equipment Life

Regular maintenance — cleaning filters, lubricating moving parts, calibrating sensors — keeps systems running within design parameters. Well-maintained equipment lasts longer than neglected equipment.

Energy Efficiency

Dirty filters, worn belts, and misaligned components force systems to work harder. Preventive maintenance keeps equipment operating at peak efficiency, reducing energy consumption.

Compliance

Many building systems require periodic inspections and maintenance to meet regulatory requirements. Preventive maintenance schedules ensure compliance deadlines are not missed.

Key concepts

Recurring Task

A recurring task is a maintenance activity that repeats on a defined schedule — daily, weekly, monthly, quarterly, or annually. Each occurrence generates a work order that must be completed.

Examples: monthly filter changes, quarterly fire extinguisher inspections, annual elevator certifications.

Maintenance Schedule

A maintenance schedule defines when and how often maintenance tasks occur. Schedules are time-based (every 30 days, quarterly, annually, etc.).

Checklist

Each maintenance task includes a checklist of steps to complete. Checklists ensure consistency — every technician follows the same procedure, and nothing gets missed.

Types of preventive maintenance

| Type | Description | Example |

|---|---|---|

| Time-based | Performed at fixed intervals regardless of condition | Monthly HVAC filter replacement |

| Seasonal | Aligned with weather or occupancy patterns | Pre-winter heating system check |

Managing recurring tasks

The Preventive Maintenance view shows all scheduled maintenance tasks for your site:

- Upcoming — Tasks due soon, sorted by deadline

- Overdue — Tasks past their due date requiring immediate attention

- Completed — Historical record of completed maintenance

Each task displays:

- Task name and description

- Associated technical system

- Due date and recurrence pattern

- Assigned personnel or service provider

- Completion checklist

Creating maintenance plan rules

To set up preventive maintenance:

- Navigate to Maintenance Plan Rules

- Create a rule and define the recurrence schedule

- Link the rule to technical systems

- Assign service providers responsible for the work

- Add checklists with required steps

Once configured, the system automatically:

- Generates work orders based on the schedule

- Populates the technical system's maintenance journal

- Notifies assigned service providers when a periodic maintenance task is approaching

Best practices

- Start with manufacturer recommendations — Equipment manuals specify maintenance intervals and procedures

- Track completion rates — Monitor how many scheduled tasks are completed on time

- Review and adjust — If a task never finds issues, consider extending the interval; if problems are frequent, shorten it

- Document findings — Record what was observed during each maintenance visit, even if no problems were found

- Link to SmartDocs — Attach relevant manuals and procedures from SmartDocs to each recurring task